Metal stamping parts are widely used in various industries from medical to consumer electronics to aerospace, agriculture, oil and gas, and many more. These parts have a significant impact on a manufacturer’s costs, cycle time, and product reliability. A proper design ensures optimal product costs, production time, and product life.

To achieve the desired output, the quality of stamping needs optimization. OEMs and other manufacturers can benefit to know the ways to improve the quality of stamping and reduce costs.

This article gives a brief understanding of the same.

Factors that affect the quality of metal stamping

The material used for metal stamping holds a crucial value in determining the strength of the material, and the design of the process. For example, steel alloys are preferred for automobile parts due to their sturdiness and lightweight.

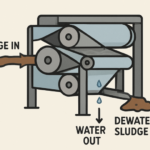

Most of the metal parts are a product of metal stamping and meet tight tolerances. Thi stamping utilizes punch press tools and dies to achieve a certain shape and size. stamping technology transforms plates or sheets into high precision components with easy operation, and high-precision stamping.

In a nutshell, the most crucial factors that decide the quality of thi stamping are:

- Design of the Metal part

- Selection of Material

- Also Selection of Blank preparation

- Selection of blanking oil

Metal stamping parts manufacturers must meet the technical requirements of the product design and stamping process. It should possess the plasticity, flexural strength ratio, plate thickness directional coefficient, and modulus of elasticity, appropriate for the required stamping operation.

The selection of blank preparation depends on the desired production volume and the material properties.

Tips to improve the quality of metal stamping

Tip #1

Collaborate with metal stamping manufacturers from the start

The design of this stamped products often overlooks the limitations of the stamping process. To avoid this, it is always best to consult the stamping experts during the design phase. Also, forecasting requirements to the stamping partners

#Tip 2

Calculate tolerances of the metal stamping.

Tolerance of metal stamping is the permissible variation in stamping. Metal stamping manufacturers require this value, as it decides the form, fit, and function of the metal stamping process.

The tighter the tolerance, the higher the production time and cost, as it requires higher expertise and expensive stamping parts to reduce the risk of failure. Therefore, manufacturers engineers need to collaborate to understand and evaluate critical tolerances.

Tip #3:

Assess each part for a perfect fit.

A good understanding of the dimensions of parts gives a fair idea of how it would finally assemble. This reduces the time to market, as it gets the design and assembly right in the first go. It ultimately enhances the overall quality of the stamping process to a great extent.

Tip#4:

Ensure Real-time quality monitoring

The stamping process must be statistical and use control systems and die sensors that help in monitoring the quality in real-time. It is an effective way to keep the quality in check and reduce the time to market, as any defect is detected and rectified before it reaches the final production stage.

Also Read: Commercial Electrical Services