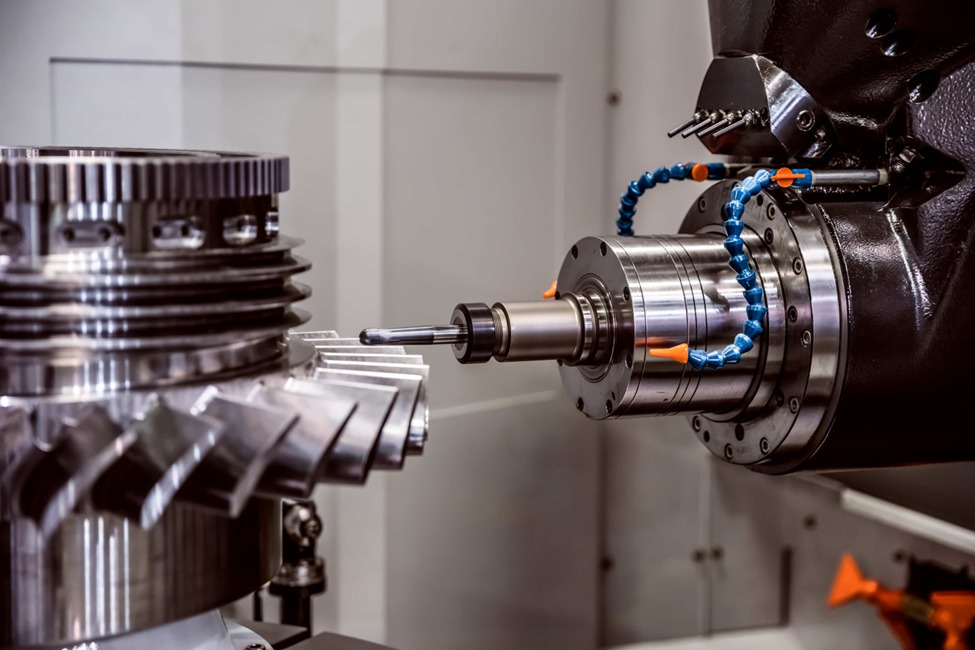

Many people do not know this, but CNC Machinery for sale is quite useful in the medical industry. That is because the medical industry is quite big as of now and is expected to reach $665.37 billion by 2028. According to a study, $12,530 is spent per person on Medicare and Medicaid Services. It is obvious that medical equipment also needs to be produced massively in such scenarios. Hence, CNC machines prove to be of quite a value in the hospitals, clinics, and all the medical places in general.

CNC machinery for sale helped during the pandemic:

During the pandemic, all the medical sectors suffered significantly because they were unable to manufacture their equipment because of the lack of the necessary medical components that were required. Experts believe that these supply chain disruption problems could lead to a struggling health industry. However, the medical industry overcame this problem with CNC machinery. The medical equipment required for surgeries and the general check-up of the patients was produced efficiently and at a faster pace. That enables the hospitals, hospices, and other clinics to receive the equipment in time without facing any sort of major difficulties.

Most used materials by the industrial machine tools:

Useable materials are quite important in the medical industry because every surgical part of the medical industry must be manufactured by keeping sterilisation and disposal in mind, in addition to the specific tension and malleability in mind. Typically, stainless steel is used by the machine to produce medical devices because of its ability to resist corrosion. However, titanium alloy is becoming more popular for other purposes like constructing bones. One, because of its ease of machining and secondly because bone made up of titanium alloy closely resembles a human bone compared to the bones made out of steel. Sometimes ceramics, polymers, and other materials are also used.

Equipment that the CNC manufactures within the medical industry:

CNC machinery for sale takes control over the manufacture of several medical devices within the industry. Due to its compatibility, the machinists have begun to take full advantage of it; therefore, several parts of the medical devices are produced by this machinery.

- Machined Surgical Instruments:

Surgical instruments require extreme precision and accuracy because even if there is the slightest change in the measurements, the instrument can become harmful during the surgery on the patient at which it is being used. CNC machinery eradicates the chances of this error as it works with extreme fidelity. It can manufacture surgical scissors, blade handles, biopsy tubes, cutters, implant holders, and forceps. The machine does not only fulfil the additional safety of these instruments but also fulfils the requirements that include the ease of sterilisation.

- Micromachining:

As the name suggests, this machine is responsible for manufacturing minuscule medical parts. The parts that it can produce include pacemakers, stents, catheters, drug delivery systems, ophthalmic devices, and drug delivery systems. These parts are mostly used in implantable devices, drug delivery systems, surgical tools and many more. CNC medical machining is also prefered over battery machinery because this does not face significant challenges with micro-implantable devices.

Read more:- Tips For Running An Effective Virtual Meeting

- Electronic medical equipment:

Previously we talked about the manufacturing of surgical equipment with the help of CNC machinery because they require precision. Similarly, electronic medical equipment like x-ray machines, heart rate monitors and MRI scanners are complex equipment that is composed of several small parts that need to be manufactured with accurateness too. The reason why CNC machinery for sale is preferred for the construction of this medical equipment is that it eliminates the risk of machine failure, especially since the machines are wheeled frequently throughout the hospital.

Hence, these machines are proven to be quite of value in the medical industry. If you want CNC machinery for your business, Flint Machine will be a good choice. They provide advanced metalworking solutions for production machining and production turning.

For more information regarding CNC Machinery for sale, it is recommended to read our commonly asked questions section.

Commonly Asked Questions:

How much can you make owning a CNC machine?

Owning your own CNC machine for your fox business can enable you to earn good amounts. Most successful CNC businesses operate on a 10-15% net profit margin. If your shop has $500,000 in annual work, you can get $50,000 to $70,000 on top of the owner’s salary.

Are CNC machines a good investment?

Yes, CNC machines are a good investment and not an expense. If you are focusing on the cost, then you are only focusing on the money that you will spend on the CNC machine, not the money which its benefits can bring back to your business.

How long do CNC machines last?

Hobby-grade CNC machines can last less than ten years. Midgrade routers can have a lifespan of roughly about 15 years, and industrial-grade routers can last for decades.